Advantages

Performance, competitiveness, eco-responsibility

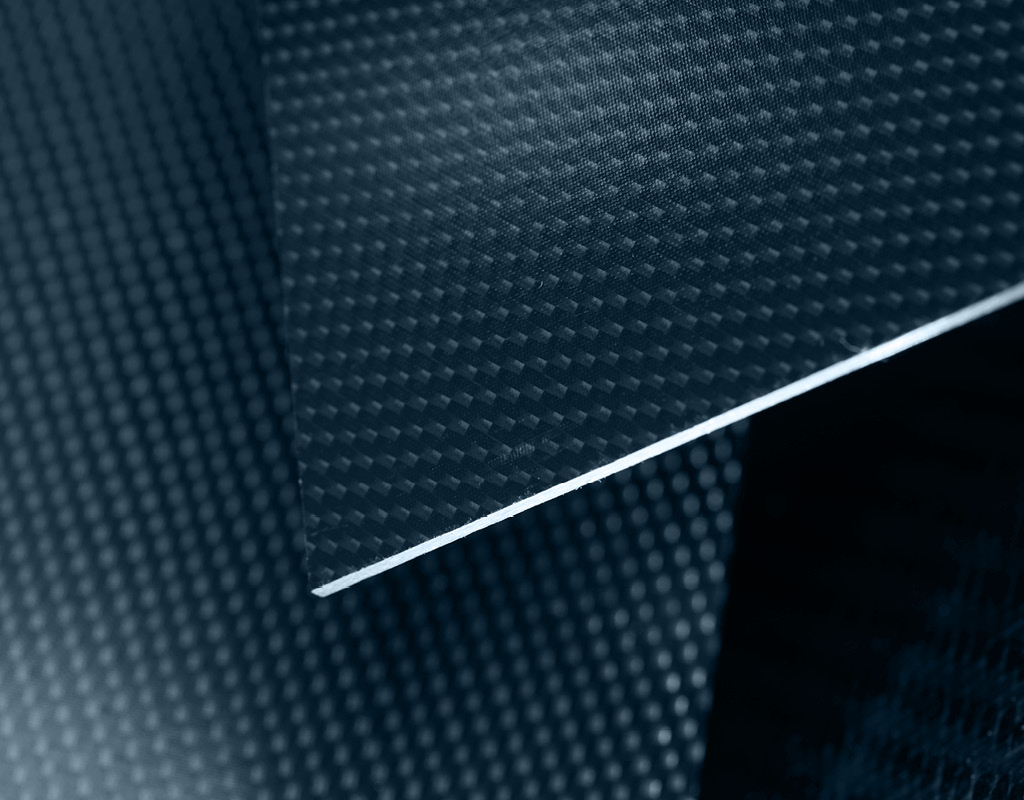

From aeronautics, U-CARBON combines exceptional performance and maximum competitiveness. U-CARBON opens new perspectives to your projects while being part of an eco-responsible approach.

Performance

A high modulus fiber that offers up to more 15% mechanical strength than commercial materials.

Competitive

An innovative process that gives a second life to carbon fiber and place U-CARBON 25% below the usual market (tariff noted on the Web).

Environment friendly

Since it is 100% recycled fiber and resin, U-CARBON is recognized as green. Moreover, its implementation generates no waste.

Technology

A robust process and a certified performance

U-CARBON ensures a very high reliability on most of the technical requirements targets.

Thermomechanical characteristics

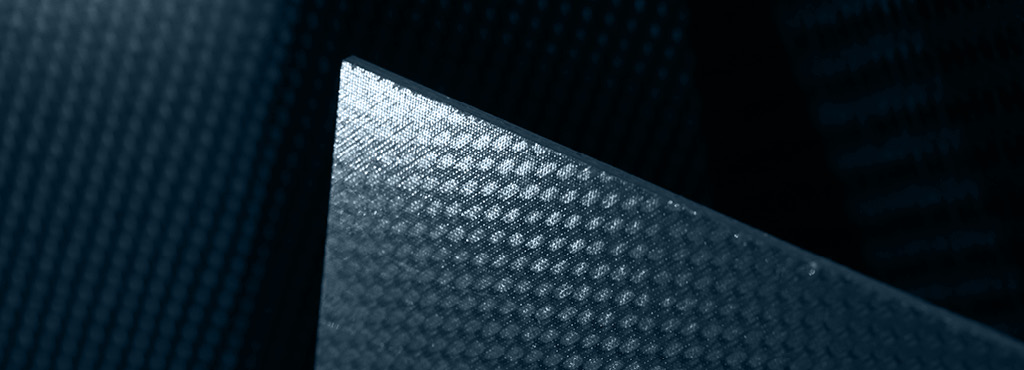

- 3k or 6k twill carbon fabrics: 0° - 90°

- Epoxy resin Tg: 180°C

- Fiber rate: 60%

- Traction module: 77 Gpa

- Tensile rupture stress: 660 Mpa

- Bending rupture stress: 960 Mpa

- Density: 1.57gr/cm3

- Max operating temperature: 140°C

- Thermal Expansion Coefficient: 2.5 x 10-6 K-1

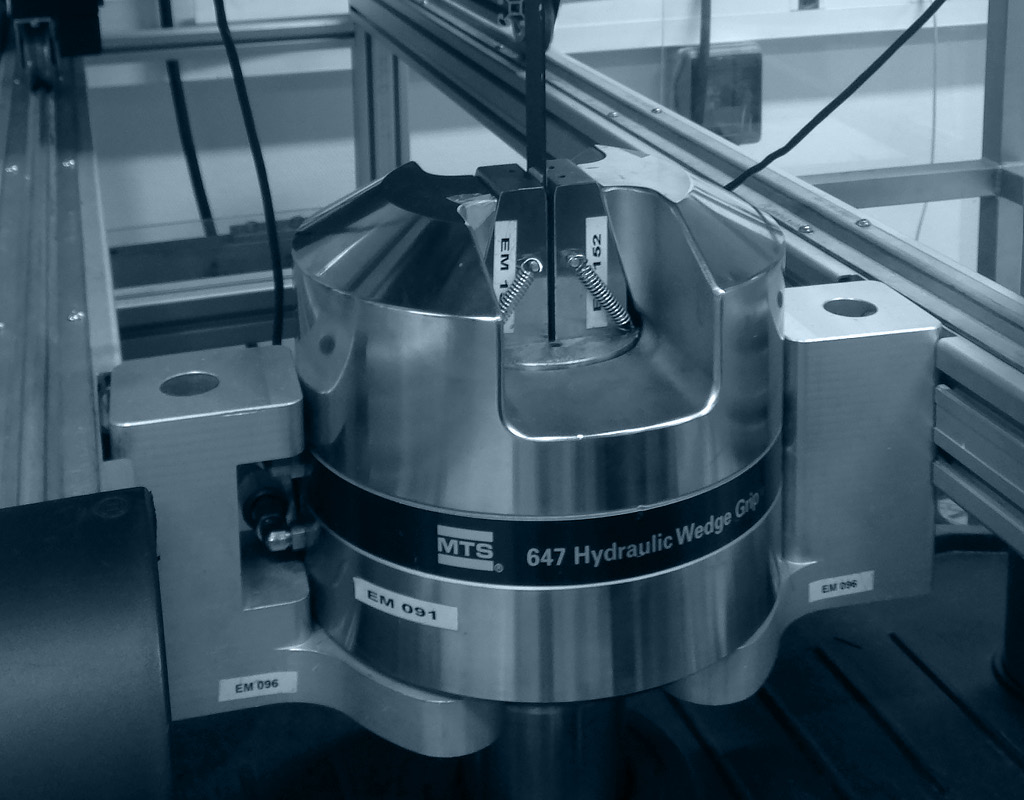

Bending test on U-CARBON

Solutions

Our skills at your service

We can support the development of your projects based on our experience. Together, we can optimize our solutions to your needs in order to achieve a maximum level of competitiveness.

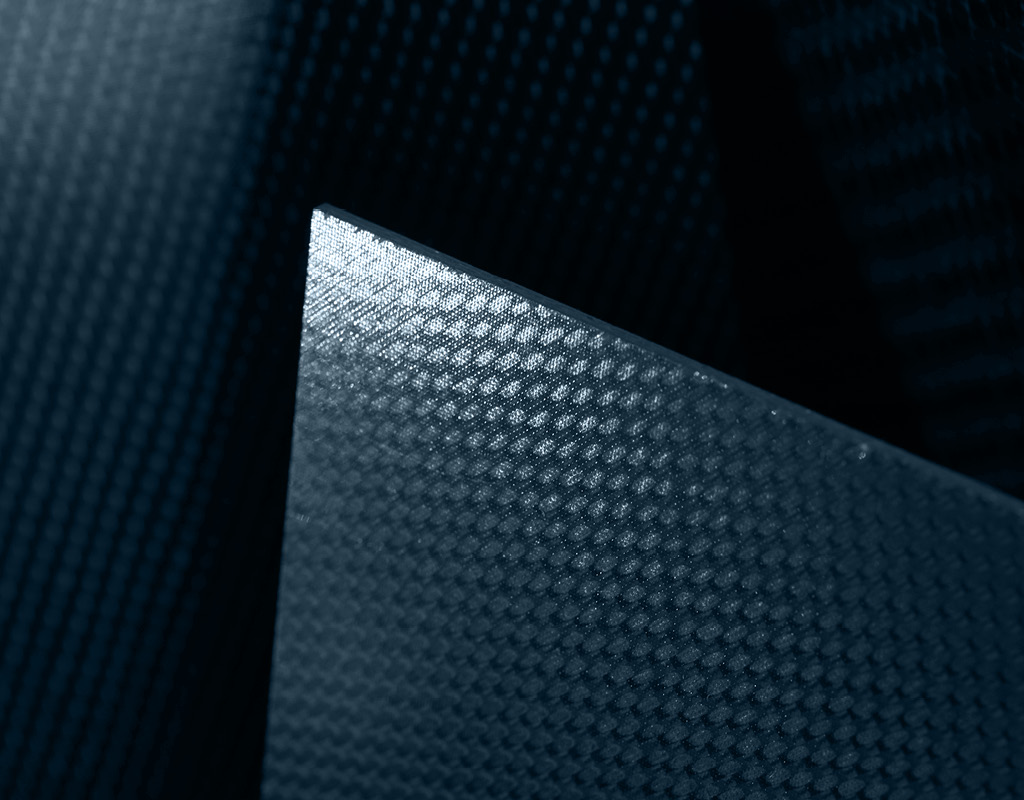

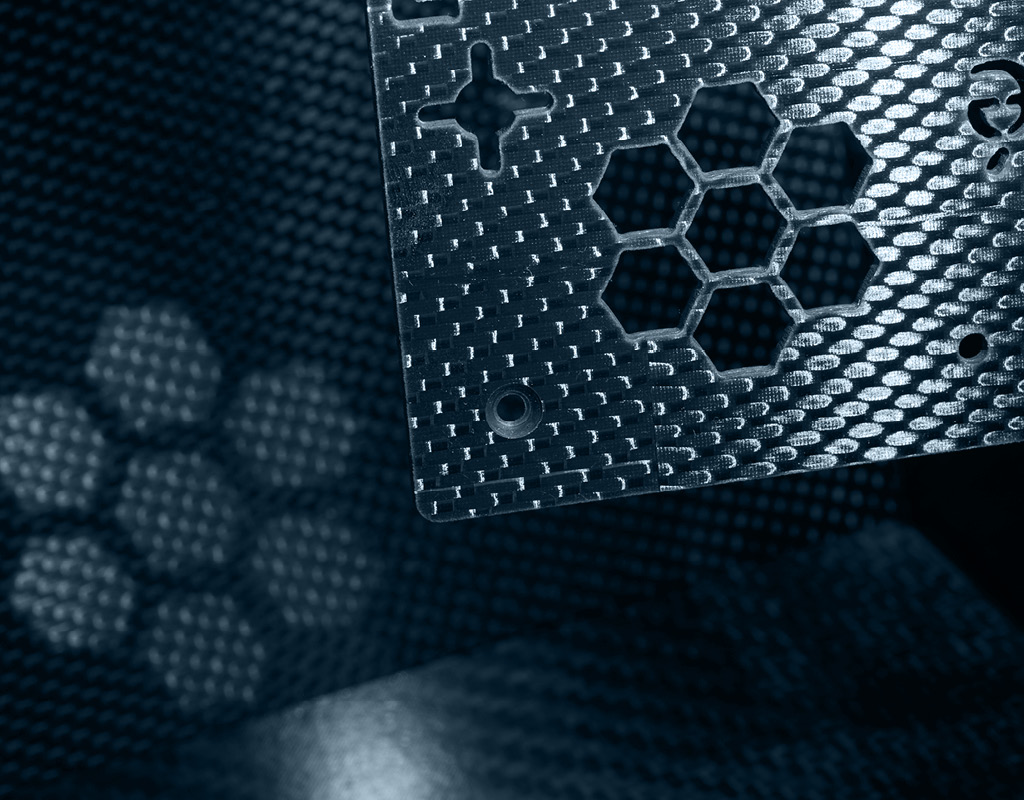

Types of U-CARBON Plates available as standard

- Process: ReUSE COMPOSITES INNOVATION

- Finishing: matt or glossy

- Available formats: L= 300 à 2900 l = 300 à 1200

- Thicknesses: 1mm to 15mm (+/-0,25mm)

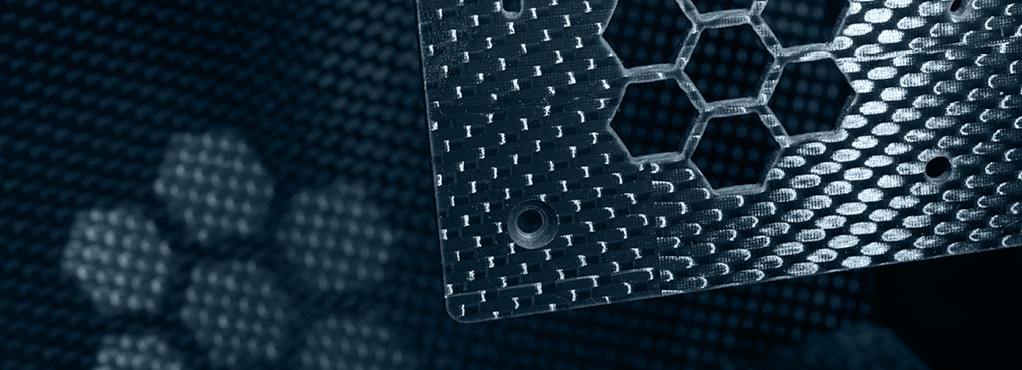

- Cutting: water jet on plan

- Sandwich: Foam / Balsa / Honeycomb

Estimate the price of your U-CARBON plate

Length (in mm)

| 300 | 400 | 500 | 600 | 700 | 800 | 900 |

Width (in mm)

| 300 | 400 | 500 | 600 | 700 | 800 | 900 |

Thickness (in mm)

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

Your price

For a personalized quote, please contact us

Quotation request

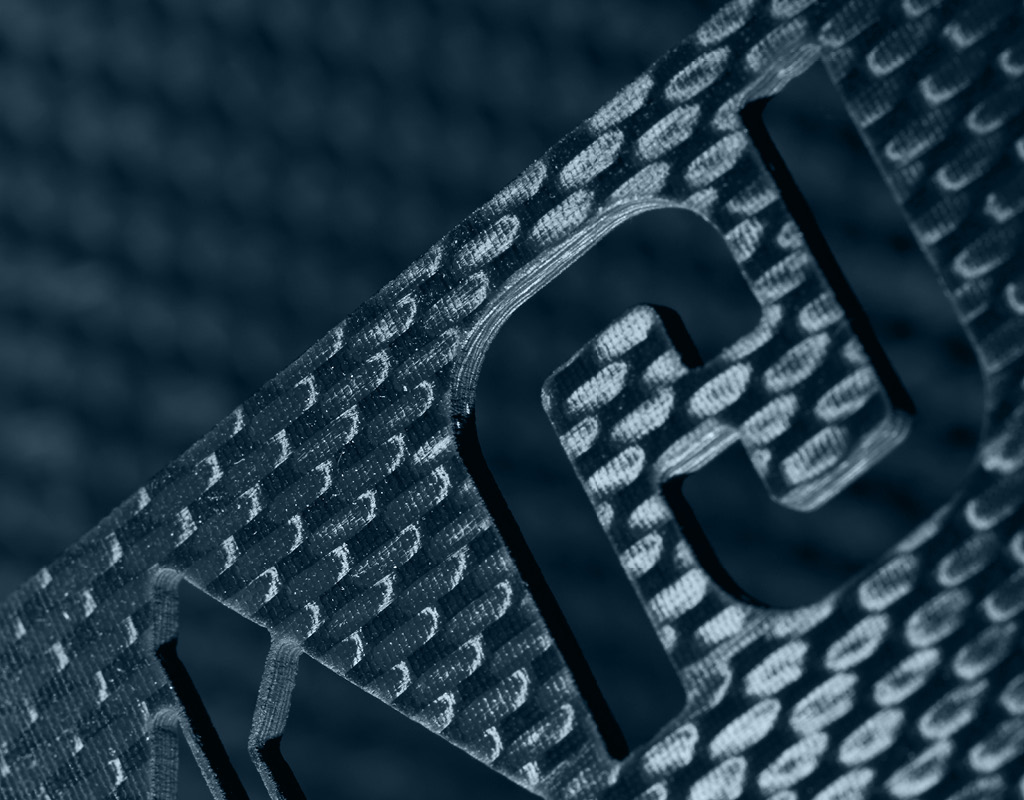

Examples of realization

Company

ReUSE COMPOSITES INNOVATION

Founded in 2014, ReUSE COMPOSITES INNOVATION‘s ambition is to realize the upcycling of carbon fiber leftover from the industry. We give a second chance to noble industrial waste. We developed and patented the material U-CARBON after set-up tuning and testing activity. Starting 2016, U-CARBON was launched for the first time in the production of drones, boating, interior design and art knife.

Activity areas

- Civil drone

- Boating

- Interior design and architecture

- Building

- Luxury

“When we created ReUSE COMPOSITES INNOVATION in 2014, we immediately focused our development activity on research and innovation. The goal was to provide technical solutions to composite manufacturers in order to reduce the impact of this industry on the ecosystem. Quickly, we have understood that this story would only make sense if we could find concrete applications of this new material. After two years of R&D, a circular economy was born between the giants of aeronautics and other business, old or new, like drones.”

Gaspard Mallet

President

Production Plant ReUSE COMPOSITES INNOVATION

Supplier partners

Specialist in cutting flexible materials for over 30 years, Omega Systems has specialized in recent years in the cutting of composites materials. Today, tier 1 supplier of aviation company, OMEGA SYSTEMS is now an important actor, known for his skill on management and mastership in composites materials processing.

Contacts

Headquarter

49 rue de la Glacière

75013 Paris

Production Plant

Parc d’activité entre Dore et Allier

1 Allée des Chênes

63190 Lezoux

Send an e-mail